Corrosion phenomenon of industrial construction projects can be seen in various industries, affected by soil, sea water, atmosphere and other corrosive media,there are various degrees of corrosion damage. Relevant statistics show that in China, the loss caused by corrosion or the cost of adopting corrosion prevention measures can reach GDP of about 4 percent. However, even if buildings and infrastructure in various industries take anti-corrosion measures, it is still difficult to realize the theoretical life cycle of industrial construction.This proves that the anti-corrosion treatment of solar mounting rack base on Saline land is Very important practical significance .

As one of the leading manufacturers of solar mounting rack in whole world , Chiko Solar Never stopped investing in the latest machinery and technology to improve production facilities. Since 2010,chiko solar has the production scale of the 1000MW roof solar mounting and 1200MW ground solar mounting. By years of production practice,chiko solar want to talk about The corrosion prevention measures of solar mounting rack on the Saline land.

First, let's look at the impact of Saline land on solar mounting rack Why Saline land is corrosive:Saline land mainly consists of a series of saline soil, alkaline soil

or various salinized and alkaline soils. The reason why salinized soil has strong corrosion is due to the effect of soluble salt. Saline land damage to buildings:

Soluble salt dissolved in water, through the continuous, capillary phenomenon to the building foundation, so that the building foundation expansion reaction, resulting in cracking of the building foundation.

In this process, the soluble salt in the aqueous solution will react with the building foundation materials and produce a series of new substances, which makes the building foundation face corrosion hidden danger.

In addition, when the materials in the building foundation are in contact with the soluble salt, they also trigger physical chemical reactions to produce new salt crystals, which form great stresses as the temperature of the building rises. In turn, it leads to the deformation and damage of the building foundation material.

Treatment of solar mounting rack Foundation corrosion Prevention on Saline land In the process of selecting solar mounting rack material, installation standard and anti-corrosion treatment countermeasure, we should combine the relevant building standards stipulated by our country.

A series of chemical compositions and mechanical properties, such as tensile strength and elongation of the yield point corresponding to the steel structure material, should meet the relevant regulations of the state carbon structural steel.

(1) in the case of product pre-treatment:

A. For aluminum solar mounting rack materials after anodizing to achieve corrosion and rust prevention role.

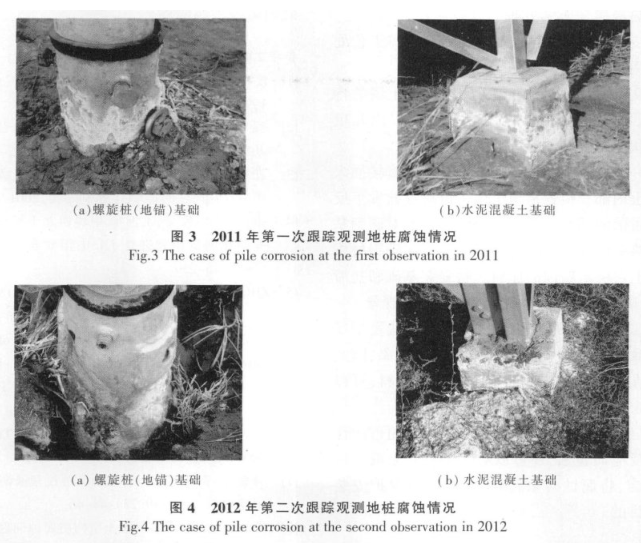

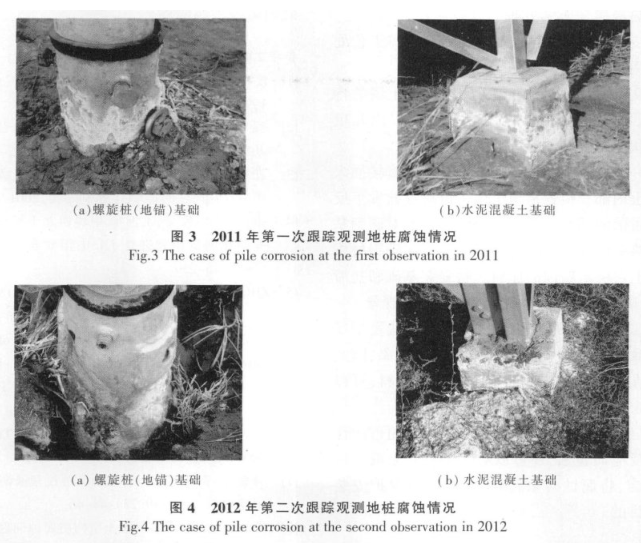

B. The steel spiral pile foundation is treated with hot dip galvanizing and anti-rust treatment.

The corrosion resistant coating is applied to the surface layer of the steel screw pile foundation to isolate the screw pile foundation from the saline soil by means of the hot dip galvanizing anti-deformation method. Fasteners should be treated with stainless steel or galvanizing.

C. According to the national standard, the average thickness of galvanizing coating should be controlled at 55 μ m and above, the anti-corrosion period should be controlled at 25 years or more, and the average thickness of zinc coating should be controlled at 30um and above. The average thickness of galvanizing fastener should be controlled in 30um and above. If the pipe member is selected, the thickness of the pipe wall should be controlled at 2.5mm and above.

(2) In terms of installation:

A. In order to avoid corrosion damage of steel spiral pile, it is necessary to avoid placing it directly in saline soil.

B. For steel ground anchors and support base connections, screw penetration connections should be selected to ensure that the support system adjusts construction deviations in the vertical height direction. The adjustable range is controlled to ±400mm based on the design elevation, and stepless adjustment can be carried out in the range.

C. Cathodic protection should be carried out on the base of the scaffold and the corrosion object is transferred to protect the foundation of solar mounting rack.

(3) In production and processing:

A. The rack fasteners produced by the manufacturer should be used.

B. In order to ensure the anti-corrosive performance conforms to 25 years engineering life cycle, all scaffolds should be pre-produced in the factory and then assembled in the field. The components are connected with each other by bolt connection, avoid spot welding.

The anti-corrosion treatment of solar mounting rack base on Saline land is a complex system engineering. Only by carrying out this work can we promote the full use of PV power station. Chiko Solar will continue to study and sum up the experience. explored and analyzed the influence of Saline land on solar mounting rack foundation. Combining with the actual condition of the installation foundation of PV power station, the anti-corrosion treatment is carried out, and the orderly operation of PV power station is actively promoted.

CHIKO Solar designs and manufactures high quality solar mounting systems for pitched roof, flat roof and ground-open areas. Whether for small or large-scale projects, standard models or tailor-made systems, we deliver what your need.Quality: With CHIKO, you will meet leading highest standard quality. All of our Aluminum profiles are made 6005 T5 with surface protection anodize oxidation 12-15 micron (µ), hooks and bolts are made of Stain- less steel 304.Ground mounting systems that made of Q235 steel will be hot dip galvanized with average thickness 80 micron (µ).In terms of installation: Chiko Solar produces solar mounting rack products with simple and fast installation, all components are pre-assembled without field cutting or welding, saving time and labor costs.

Production Certification: CHIKO Solar have obtained product certifications, and management system endorsement granted and approved by leading testing agencies including UL、 SGS 、Gamcorp、 MCS 、

Intertek, SPAD etc. Our product designs are based on the following Australian Standards and sections of Building Code of Australia relevant to structural issues.

Above news from CHIKO Sales & Marketing department

Above news from CHIKO Sales & Marketing department

Add: No 680 Xingwen Rd. Jiading dist. Shanghai 201801 China

Phone: +86(21) 59972267 59973712 59973713--811

Fax : +86 (21)59972938

Email: Chiko@Chikolar.com

Website: http://www.Chikolar.com